Resin printers have leveled up at an insane pace over the last few years. We’ve got large format printers like the Jupiter SE 6K (Our review) with its massive print volume, the Neptune 4 Max with an even LARGER print format, and the crazy-high resolution on the Mars 4 9K. What if we can find a happy medium between large and ridiculous, but also push the resolution even higher? That’s precisely what the Saturn 3 Ultra is looking to do. With a 12K resolution, a large build volume at 218.88mm(L) x 122.88mm(W) x 260mm(H), and a huge refresh of the long-running Elegoo operating system, could this be the new flagship for resin printing? Only one way to find out!

Before we dig into printing, let’s get a look under the hood. The Elegoo Saturn 3 Ultra has a ton of new features, not all of which are obvious, that it has cribbed from other Elegoo printers. Setting up the device, I found something new around every corner. Let’s unbox it.

Inside the box, there’s a USB-powered charcoal air purifier, a stack of paper funnels, extra wrenches and screws, two paper masks, a metal and plastic scraper, a pack of non-nitrile gloves, a license card for Voxeldance Tango, a USB stick, and the power supply for the unit.

The most obvious upgrade for the Saturn 3 Ultra is the 12K mono LCD. Measuring 10 inches and with a resolution of 11520×5120, and an XY resolution of 19×24μm, the hardened glass powers the masked stereolithography (MSLA), just like any of Elegoo’s most recent printers. It does so with a COB (Chip on board) plus refractive light source, which is to say it has the same angular reflection system that we saw in use in the Jupiter SE. On the back are two vents, though they don’t stick out and are not angled like the Jupiter SE, but they utilize the same cooling structure behind the scenes. Two copper tube systems and oversized cooling fans help keep the LCD and all the rest of the internals cool, extending its life.

I was surprised to see the new vat that ships with the Saturn 3 Ultra. Instead of the clear FEP that I’m used to seeing on all of my resin printers, this FEP is fairly opaque – when you see what looks like a cloudy FEP, don’t stress. This new FEP is called nFEP, and reports are that it lasts longer, releases easier than standard FEP, and somehow is cheaper than standard FEP film. This nFEP is made from PFA, or perfluoroalkoxy. The tensile strength of a standard FEP is around 24.3 mPa on average, whereas the nFEP pushes that to 29 mPa. This means that the cured layer that was just printed peels away from the print bed easier, without flexing the surface as much. As the nFEP isn’t moving as much, the layers shouldn’t stick as often, and the layers shouldn’t shift as often. Proof is in the pudding though, so we’ll be testing this over time across multiple prints.

The other obvious change that I saw was an improvement to the Z-axis screw. Utilizing a dual-rail system with an oversized ball screw improves the stability and movement of the print assembly. In addition to being quieter, it’s also more accurate than before – 0.01mm more to be precise, resulting in 0.01 to 0.2mm layer heights. It’s hard to imagine 12K resolution and layer heights that small, but even at higher print speeds (up to 150mm per hour), the resulting prints are incredibly detailed, as you’ll see in our macro pictures.

Coming from my Saturn 2, I was happy to see the new laser-etched build plate on the Jupiter SE. This has also made its way to the Saturn 3 Ultra. I found that this removed the need for scuffing the plate for printing, with the added bonus of being easier to remove prints from the plate after the fact. That’s not the only trick the new plate has to offer.

The Jupiter Se uses a new four point leveling system instead of the ball joint system present on the Saturn 2. I utilize a magnetized plate on my Saturn 2 and the force of removing that magnetic plate has occasionally ruined my leveling as it’s effectively held in place by a single point. The four point leveling system on the Saturn 3 Ultra instead really only articulates up and down, and rocks forward or backward. As a result, once I leveled the plate, it stayed leveled. I’ve pushed and pulled on this plate quite a bit and it hasn’t budged one bit. It also attaches differently, sliding on to a jam nut held in place by a spin crank above. It’s a combination of the Jupiter SE and the Saturn printers, and made better by the amalgamation of both. I leveled the plate on camera in the video above – see for yourself.

The cover on the Saturn 3 Ultra gets an aesthetic change, moving to a smoked gray look rather than the trademark bright red acrylic. Other than looks, I asked Elegoo what improvements this new hood brings. They informed me that the new cover blocks between 95 to 99% of all ambient UV light, exactly the same as the red hood. They were quick to point out that no hood out there will stop the sun, so blackout curtains are still highly recommended. I know some users have reported resin curing in their vat while sitting idle, but I have yet to have that experience myself.

Opening up the OS for the first time, I was pleased to see a huge upgrade. The screen is a color touchscreen that keeps the simplicity of the previous iterations, but adds a lot of important information about your prints to the mix. The first panel is Print, Tool, and System, as it always has been. Under Tool, you have manual controls for the plate (including a 50mm move option, thank you!), the zero for your Z-axis, tank cleaning, a screen exposure adjustment, a device self-test, and the master stop button. The exposure test can be done as a grid, or with the Elegoo Technology logo to ensure your device is operating as intended.

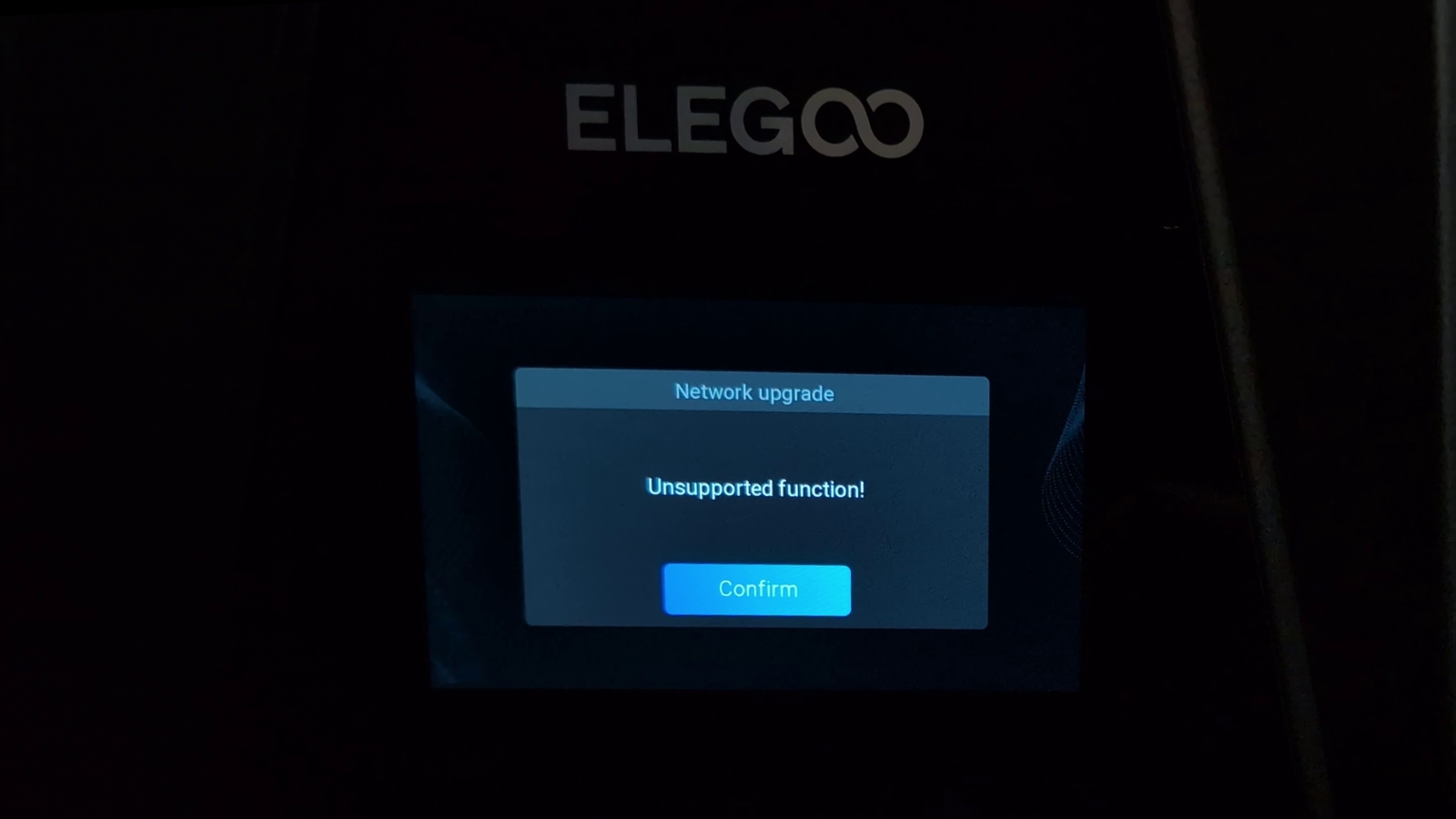

The Saturn 3 Ultra has a wireless whip to attach to the side of the device, allowing you to send files to your device remotely (at somewhere between 6 and 8Mbps). That’s highly dependent on the software you use — it currently works in Chitubox and Voxeldance Tango, but I was unable to find the right option to make it work in Lychee Slicer. What I wasn’t able to get working however was remote firmware updates. Instead, it throws up a generic error that doesn’t really help you diagnose the situation, but suffice to say, it just doesn’t work. Instead you’ll be updating with a thumbdrive, as you always have. Perhaps the next update will bring that functionality?

With the device set up, and resin loaded in the vat, it was time to print. Popping open your slicing software of choice, each has the ability to download a profile for the Saturn 3 Ultra. I could certainly print the Cones of Calibration V3, the included rook, or any other number of test prints, but those aren’t very fun, are they? No, instead I printed a bust of Medusa from Loot Studios. This model is highly detailed, beautiful, and has a lot of small bits like the teeth on her snakes. You can see how Loot Studios showcases it and the other goodies in this bundle right here:

With a file sliced and loaded, we now get to see a new screen for this OS update. With the sliced file loaded you’ll be greeted with a screen showing the file name, normal and bottom exposure time, print height, model height, a high-detail image of the object being printed, the status of the device, time elapsed, and time remaining are all displayed on this main screen, as well as whether you are connected to a file on a thumbdrive or if you are streaming it from your wireless connection. While you aren’t likely to be making changes on the screen before allowing your print to continue, you actually can.

The resin I chose is a semi-transparent milky affair. It’s also thin and cheap. I figured it’d be the second checkpoint for the Saturn 3 Ultra. Can this flagship print directly out of the box with only default settings and the most economic non-matched resin I could find on Amazon? Well, it turns out the answer is an emphatic yes.

While I appreciate the milky look that came out of the print, it just wasn’t very easy to read detail on it. Instead I hit it with a darker gray primer, bringing out a metric ton of detail. Judge for yourself!

I wanted to make sure it wasn’t a fluke that I was able to just throw a file in and print it, so I printed a dice tower using a standard 4K Elegoo resin, and then a Porg from Star Wars in a light gray from Sunlu. All of them were washed, cured, and then primered to bring out their detail, and it certainly did. The quality was high, the edges were sharp, and all the pieces printed without a hitch.

I printed the dice tower in two halves and then printed the Porg sitting flat on the plate without any supports. Both printed perfectly, and on the first attempt. The new nFEP and laser-etched plate combination seems to be delivering in a way that we’ve not seen, even in Elegoo’s other printers. The fact that it handled resins of all qualities and viscosities without doing anything beyond the defaults is frankly astonishing. I’ve leveled it once when I did it on camera, and that’s the last I’ve had to touch it beyond loading files and enjoying the results. It feels like Elegoo has taken a huge step forward with this new OS, screen type, and other improvements. Could this be the last step before we get automated leveling? Put plainly, 3D resin printing can be complicated, messy, and challenging to get working correctly. It’s nice when somebody makes it all easier.