Earlier this year the Elegoo Centauri Carbon made waves as an enclosed CoreXY printer that punches above its weight class. Can Elegoo's first CoreXY model truly challenge twice-as-priced rivals? After more than 200 hours of use, it performs on par with those higher‑priced competitors, though not without a few trade-offs.

The printer comes assembled and can go from box-to-calibrating within minutes. Initial setup involves removing three screws that kept the print bed in place during shipping, attaching the screen, spool holder and top glass. The printer was then ready to run through its calibration. Compared with all of the other printers I've used, the calibration on the Centauri Carbon takes the longest; I didn't time it, but it's roughly a 20-minute process. The one-click self-check takes care of automatic leveling, PID tuning and input shaping. On paper, the calibration should align all the settings for perfect prints; however, the Centauri Carbon requires a little bit of manual tweaking. Unfortunately, I only discovered that the z-offset and elephant-foot compensation need a bit of adjustment after I spent over a few weeks printing a large project. More on that later.

Now that we're set up, let's discuss specs. It features a CoreXY mechanism capable of up to 500 mm/s, a 256x256x256mm build volume, a chamber camera paired with a weak light, a dual-sided print plate, power loss recovery, a filament run-out sensor, a nozzle wiper, a waste chute and side-mounted filament holder. An enclosed CoreXY with a fast print speed and volume of 256x256x256 sounds familiar ... ah yes the Bambu Lab P1S priced at $699. By contrast, the Centauri Carbon costs just $299. The dual-sided print plate is interesting: one side uses a textured PEI sheet for PLA, PETG, ABS, CF, etc., while the other side is a low-temperature PLA specific plate for printing at 30ºC. The touchscreen controls are easy to use and straightforward. I have an earlier model, so my machine has the tiny bead light, which is practically useless. Newer machines have two light bars that, from what I have seen online, work fairly well. Elegoo has offered to upgrade the light for those who request it, but as of this writing, the upgrade program has not begun.

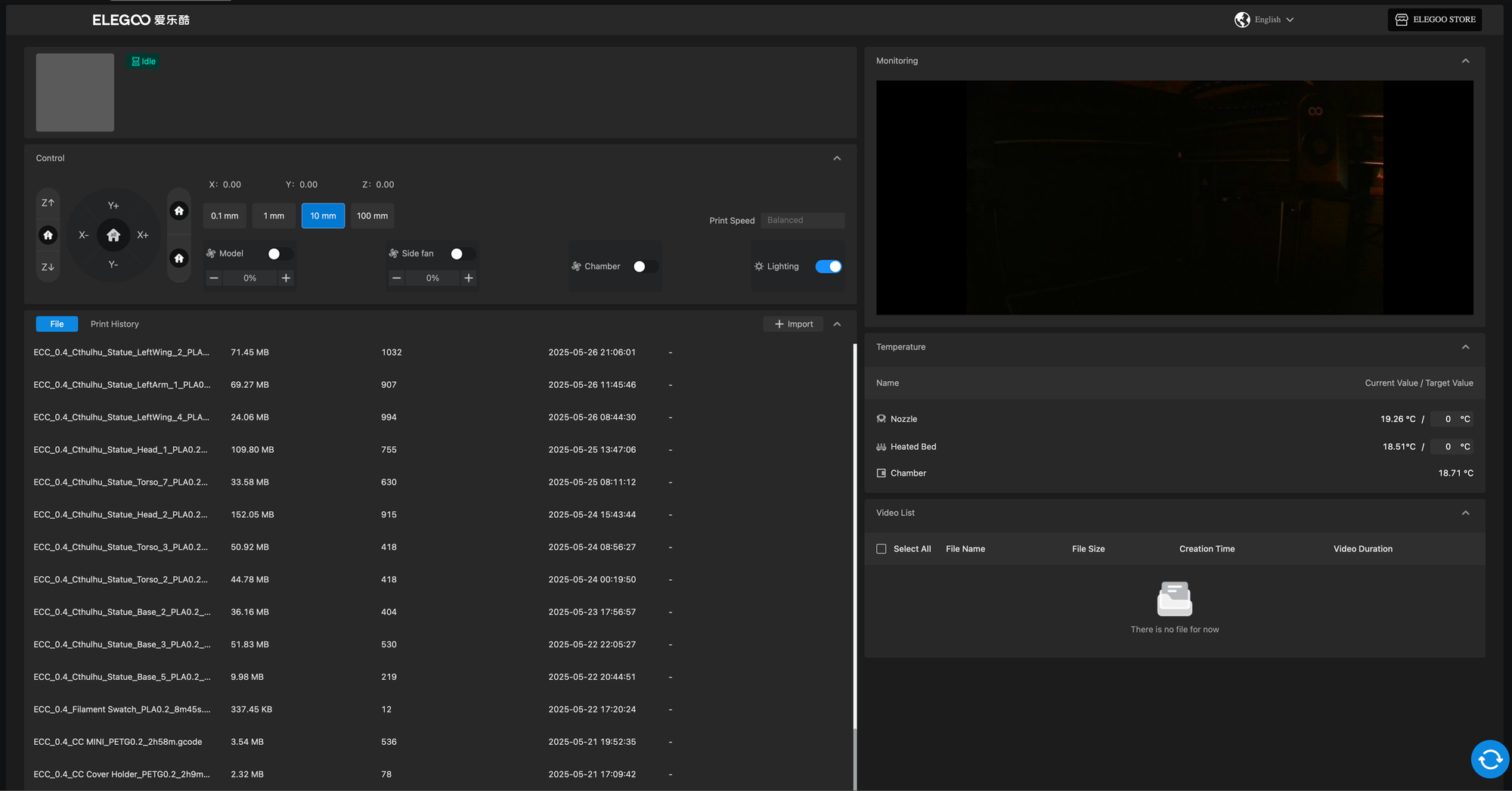

Let's talk software. For all of my printing with the Centauri Carbon, I've exclusively used Elegoo's slicer. Yeah, I know, another slicer to add to the collection but I like having print profiles come directly from the manufacturer. At least it's a fork of Orca so it works well right out of the box installer. On the machine itself, Elegoo uses a proprietary firmware and not Klipper which is kind of a bummer if you're a tinkerer. Proprietary firmware limits customization options, but for non-tinkerers this simplifies the experience. The web interface clearly draws inspiration from Klipper/Fluidd, providing basic controls, file list, print history and video monitoring. As of this writing, the only management tools Elegoo provides are the web UI and the “Device” tab within Elegoo Slicer. There is no dedicated mobile app so you can't check progress while out of the house or push notifications if something goes wrong. With a little bit of effort, I was able to get those features using OctoEverywhere which has been nice.

Reliability is stellar: after hundreds of hours, zero nozzle clogs, layer inconsistencies, or mechanical failures. Performance wise, I've been impressed. I had no plate adhesion issues, except my first print PETG print, which required a slight adjustment to the bed temperature. The surface finish is pretty smooth and uniform. Noise levels depend on material and speed. Elegoo recommends printing PLA with the enclosure open; because PLA prints quickly, this configuration can be noticeably louder. When I printed PETG with the lid on, the noise level was dramatically reduced. Since there's no chamber heater, printing ASA was a bit of a pain. I had to heat-soak the chamber by setting the bed to 110ºC with the lid on and the fans off for 30 minutes so the chamber could get above 40ºC. This felt like a waste of time and energy but I guess the Centauri Carbon can't have it all at such a good price.

The printer's on-board memory comes with a few sample files to print. I printed a miniature Centauri Carbon which hooks below the waste chute to catch the purges as well as a side-mountable holder for the glass top when it's not in use. These turned out great, as expected since they're tuned for the machine. I wanted to print something bigger ... much bigger to really give it a test, so I settled on printing the Rise of Cthulhu statue and dice tower from Loot Studios. After weeks of printing and multiple spools of filament, the 22" tall and 28" wide Cthulhu was a sight to behold. When assembling Cthulhu I noticed a very minor elephant's foot on all of the prints which is how I discovered the z-offset still needs manual adjustment after the calibration. Oddly, the z-offset can only be changed while a print is running. After I increased the z-offset and elephant-foot compensation in the slicer from 0.10mm to 0.27mm, I've had zero issues going forward. Although it's slightly annoying to have to change the z-offset after every calibration, I've only needed to calibrate once since the initial calibration because I moved the printer to a different table.

The Centauri Carbon is a CoreXY performance bargain for most users. It delivers build volume, speed and reliability rivaling printers at twice the price if you print PLA and PETG. ASA/PC users might want to consider something else if you don't want to deal with the extra steps required by not having a heated chamber. For budget beginners chasing premium specs, it's unbeatable. For hobbyists prioritizing large aesthetic prints (like my 22" Cthulhu), it's a solid workhorse.

Elegoo Centauri Carbon

Excellent

The Centauri Carbon is a CoreXY performance bargain for most users. It delivers build volume, speed and reliability rivaling printers at twice the price if you print PLA and PETG. ASA/PC users might want to consider something else if you don't want to deal with the extra steps required by not having a heated chamber. For budget beginners chasing premium specs, it's unbeatable. For hobbyists prioritizing large aesthetic prints (like my 22" Cthulhu), it's a solid workhorse.

Pros

- Great performance for an incredible price

- Nearly pre‑assembled; just remove three shipping screws and it’s ready to calibrate

- One‑click self‑check (auto‑leveling, PID tuning, input shaping) makes the first‑time setup painless

Cons

- Bad light and tinted front glass makes it hard to see inside

- Calibration still needs manual z-offset/elephant-foot tweaking

- No chamber heater

This review is based on a retail unit provided by the publisher.