If you’re familiar with Formlabs, it’s probably in the commercial space. As a manufacturer of 3D printers, they have mostly focused on professional printers that put anything in the consumer space to shame. They have printers that use Stereolithography, just like printers from the likes of Elegoo or Prusa. They also have printers capable of handling more complex materials using lasers (powder burning with a laser - Selective Laser Sintering (SLS), Masked Stereolithography (MSLA), and more). Combined with other techniques like thermoforming, injection molding, silicone molding, and more, these printers are capable of creating incredible, functional prototypes in the blink of an eye, speeding products to market, creating new tools, and refining existing ones. There’s no doubt that they are incredible printers, but they tend to be out of reach for the average consumer. Thankfully, they’ve got a new product that not only takes some of their incredible engineering advancements in the resin space and brings it to that consumer market, but also tackles an area where few manufacturers seem overly concerned – safety. That safety aspect is where we’re going to start, and then we’re going to print a few things and see how the resin performs. Let’s get started.

If you missed my review of Elegoo’s Mars Mate air scrubber (review), you might have seen that there are a number of terms you should know, the first of which is VOC. VOC stands for volatile organic compounds, a grouping of chemicals that can be harmful if inhaled including (but not limited to) benzene, ethylene glycol, formaldehyde, methylene chloride, tetrachloroethylene, toluene, xylene, and 1,3-butadiene. It doesn’t take a chemical engineer to know that none of those things are likely good for your lungs. The second term is TVOC, or Total Volatile Organic Compounds. While they sound like the same thing, TVOC is the measurement of gas per classification and the sum of all gasses in a space. That is to say, it’s your overall air quality and its component parts. TVOCs are typically used to measure the amount of toxins in an enclosed space, such as the room where we’ll be performing our 3D printing.

Your household actually contains a number of VOC-emitting items. All of the solvents and cleaners under your sink, dishwashing detergent, bleach, shampoos, deodorants, fabric softeners, dryer sheets, floor cleaning solutions, wood polish, adhesives, and even the air fresheners we use to try to mask all the smells from this list all contain some level of emissive chemicals including acetaldehyde, phenol, methylene chloride, formaldehyde, limonene, benzene, phthalates, toluene, and more – it reads like a horror show. And to think, these are things we use to clean other things! In small doses, it’s unlikely these will hurt you, but over time they can be toxic, but what does the scale look like? Any sensor we’d use measures the milligrams of VOC per cubic meter of air, which is why all of the results appear as TVOC mg/m3.

Unfortunately I don’t have a lab or a commercial air sniffer to break down the chemical composition of these resins, but here’s the thing – they aren’t doing it either. Or at least they aren’t telling you if they are.

For just about any chemical you can buy on the market, whether it’s a food, nail polish, floor scrubber, or eyedrops, the Occupational Safety and Health Administration (OSHA) mandates that manufacturers, distributors, and importers of hazardous chemicals create what are called Safety Data Sheets (SDS) and ensure they are provided to those who might use those chemicals. These are to be provided to employees for the purpose of training, and to ensure that these chemicals are handled safely.

That’s not where we are today.

Right now there is a bit of a gold rush in the 3D printing space, and resin producers are well aware of that. They are also well aware that there is a severe lack of stringent regulations and inspection, lack of regulatory enforcement, and cost-cutting measures to remain competitive. We’ll focus on a specific chemical that has come up frequently in many of them – 4-Acryloylmorpholine (ACMO). The EPA requires that ACMO be reported on the SDS, but frequently the SDS is either not reported, incomplete, or simply does not disclose the chemical. While I’ll be completely unable to detect it for myself, the Formlabs team has taken a stand with this new Creator Series resin. They’ve used their independent lab tests to check out many of the big-name manufacturers to see where they land in both providing an SDS, and whether ACMO is present in their popular products. You can grab a copy for yourself right here.

Additionally, they’ve provided their own SDS, disclosing the full chemical composition of their resin up front, and that no ACMO is present. They also provide a full accounting of what is present, and how best to handle it safely. See for yourself.

In all of my videos I’ve been extraordinarily clear about the need for proper personal protective equipment such as respirators, but not everyone is either aware or heeds those warnings. In the space where I’m testing I have four active resin 3D printers, one combined wash/cure station, and one that is separated into two – a wash station and a cure station - I also have two filament printers. I need my lungs for…you know, breathing, so it’s important that I keep this space well ventilated and safe.

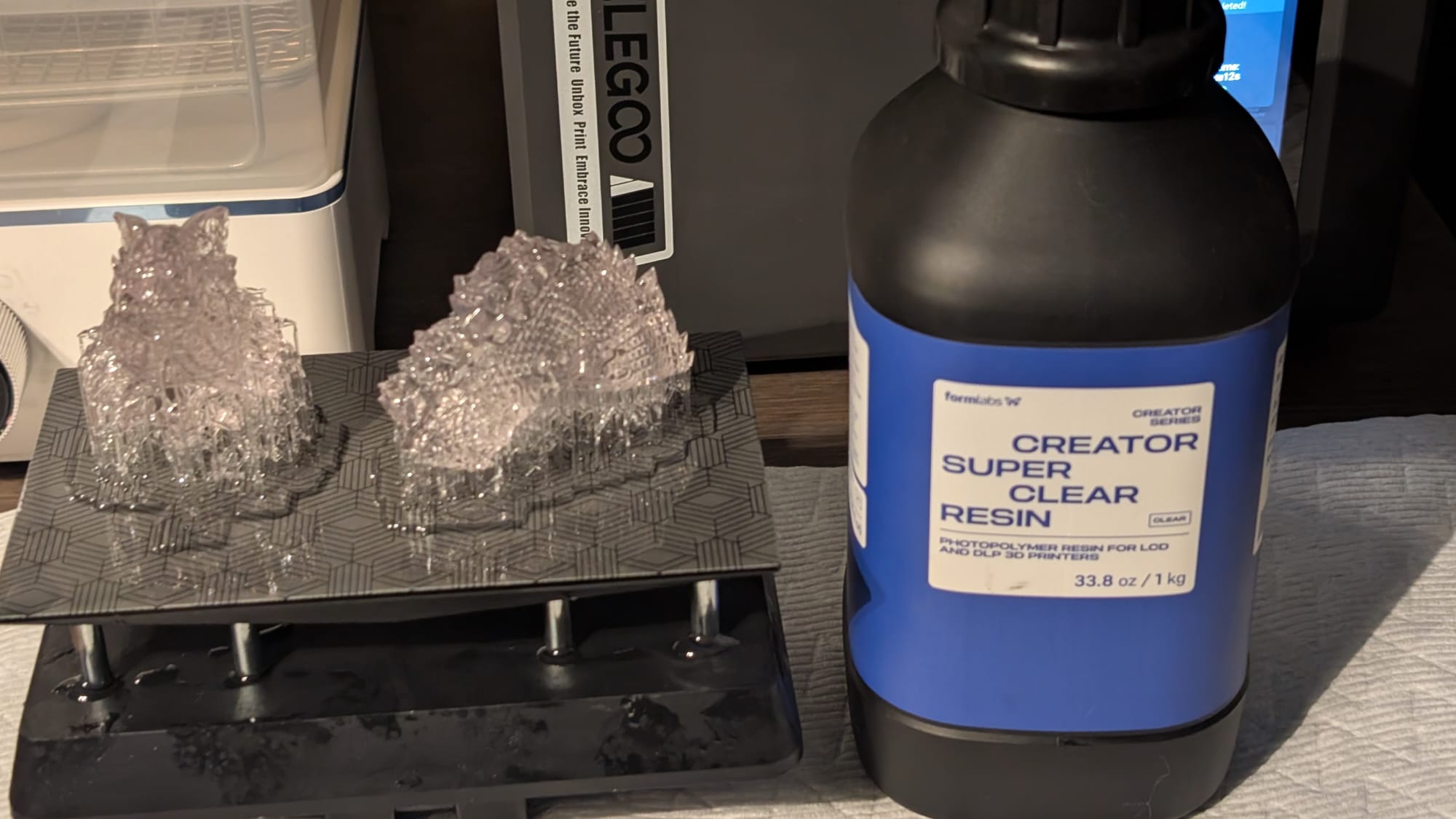

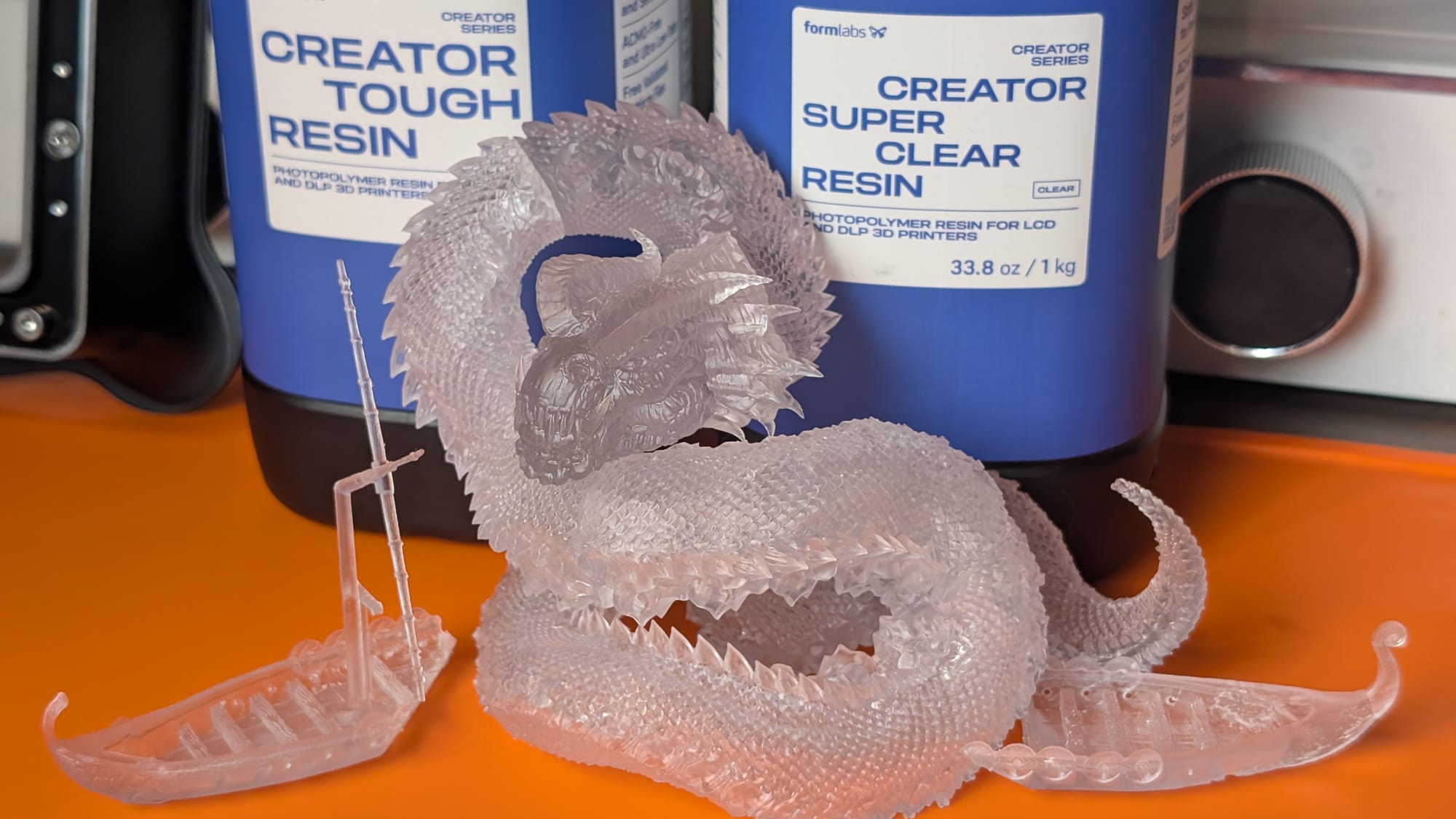

Recently I got to test out the new resin from Formlabs. Aimed at the hobbyist market, their new Creator Series resins are ACMO-free, safer, and supposedly low-odor. I checked out their Creator Tough Resin - an impact-resistant and semi-flexible gray resin that is meant for figures, statues, and just about any other model you might want to fit. I also checked out the Creator Super Clear Resin – a stiff and strong clear resin (It's kinda in the name) that is meant for both LCD and DLP printers alike.

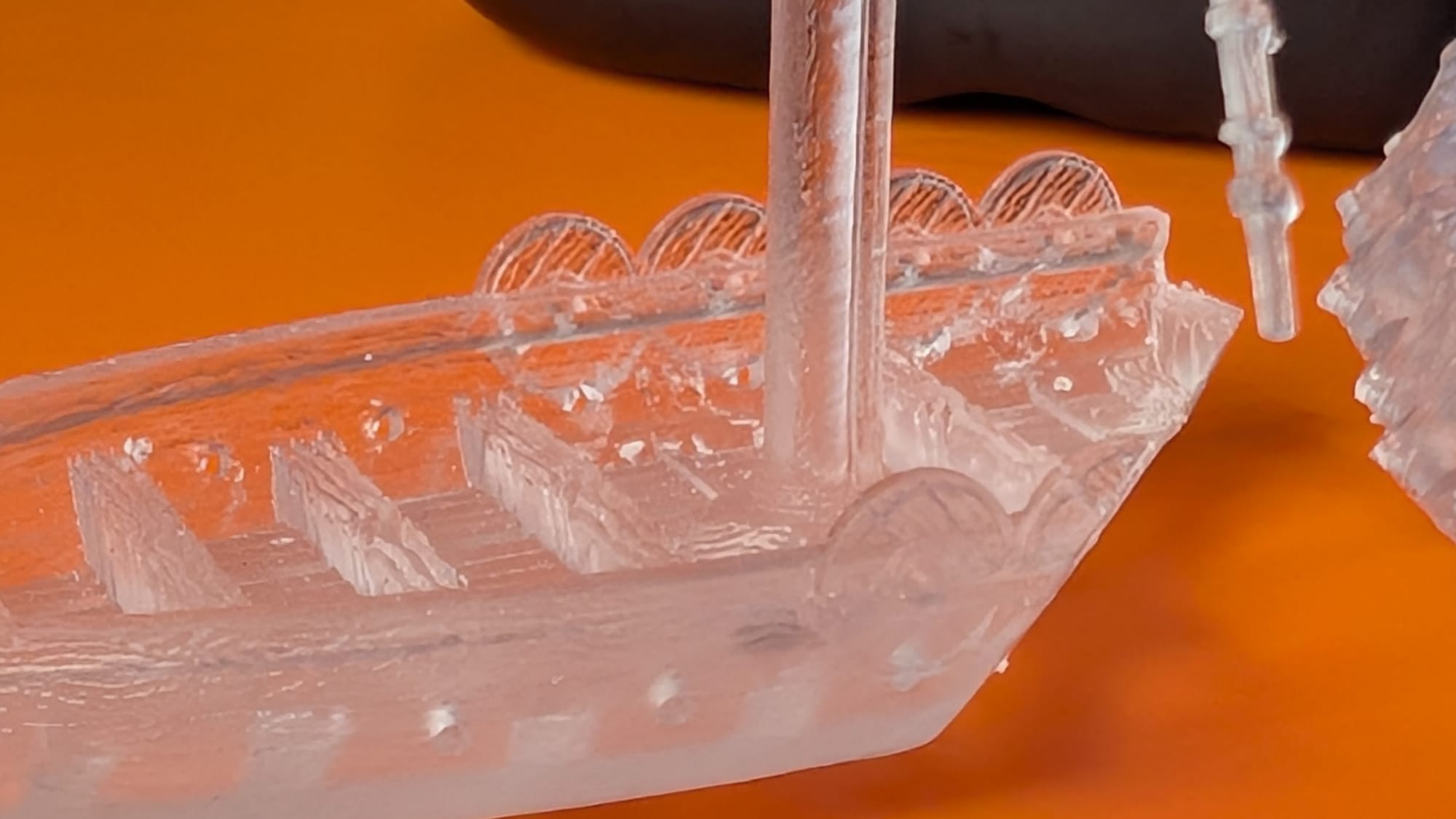

Cracking open the Creator Super Clear Resin, I put it to work on a small version of Jörmungandr – the Midgard Serpent (also known as the World Serpent) in Norse mythology. He is the massive beast that encircles the entire realm of Midgard.

As you can see, Jörmungandr and the cracked boat he’s sitting on printed flawlessly. There isn’t a blemish anywhere on the print, and it truly is, as it says on the bottle, “super clear”. Best of all, I didn’t have to take any special steps with post processing to get it that way. I let it air out for 12 hours after a two-stage wash, as I always do, and then hit it with another wash of isopropyl alcohol to shine it up. You can see the results for yourself throughout this article.

This is one I’ll likely slot an LED inside to really make it shine with all of the clear facets. It should also work well for light sabers and detail elements. I can’t overestimate how clear this resin really is – you can hardly see it in the vat. Frankly, I’ve never seen resin this transparent.

Opening the Creator Tough Resin, I have to be honest, it is an assault on the nose. Low odor it is not. The good news is that a quick check of the SDS, it doesn’t mention needing a respirator. What I smell isn’t toxic. It’s strong, but it’s not going to hurt you. Still, it caused me to throw a respirator on pretty quickly. Your mileage may vary, but for me it’s an eye opening experience every time I open the bottle.

Putting it in the tank, it seems to be a bit thinner than other resins I’ve used, and slightly darker – likely due to whatever formulation the Formlabs team has put together for it to be safe. Just like with Jörmungandr, though, it turned out a completely flawless print. Printed at full speed on the Elegoo Saturn 4 Ultra 16K, Ludo from Labyrinth came to life! As you can see below, the details are sharp, clean, and without a single seam or blemish. The supports came off like they were barely attached, and I can’t see a single attach point, despite the darker color.

There is one downside to a resin that’s carefully curated, safe, and can deliver consistent results – it’s not cheap. While your run of the mill ABS-like resin will run you roughly $18 per 1KG bottle (including the new tariff garbage we all get to deal with), the Formlabs Creator Series will run you $45, though at the time of writing it’s on sale for just $22 for either bottle. I don’t know if that price will hold, but that’s par for the course for anything right now, isn’t it?

I’m hesitant to score this like I would a normal product as that’s not really the point here. Instead, I’d rather turn to Formlabs CPO Dávid Lakatos for his thoughts:

"As the hobbyist market grows, it’s exciting to see the impact and power of 3D printing in the hands of creators. However, there’s a concerning gap in the safety of the resin options currently on the market, so we tapped the experience of our leading materials science team to deliver innovative, high-performance, safer, and low-cost resins. As another step towards making 3D printing accessible, Creator Series will empower more users to experiment, innovate, and create with confidence."

A safer resin that you can be sure doesn’t contain toxins that could cause long-lasting damage to your lungs, eyes, and skin is an important step for this industry. Nobody is saying not to wear your personal protective equipment, but a material to print with that ensures you stay safe even in a spill is a step in the right direction. Frankly, it’s one this industry needs, and it’s one I hope we can all take together.

Big thanks to Formlabs for letting us take a look at their latest innovation. Hopefully it’s a path they continue down and we can all benefit from their work. If you want to take it for a spin yourself, you can find the Creator Tough Resin here, and the Super Clear Resin here.