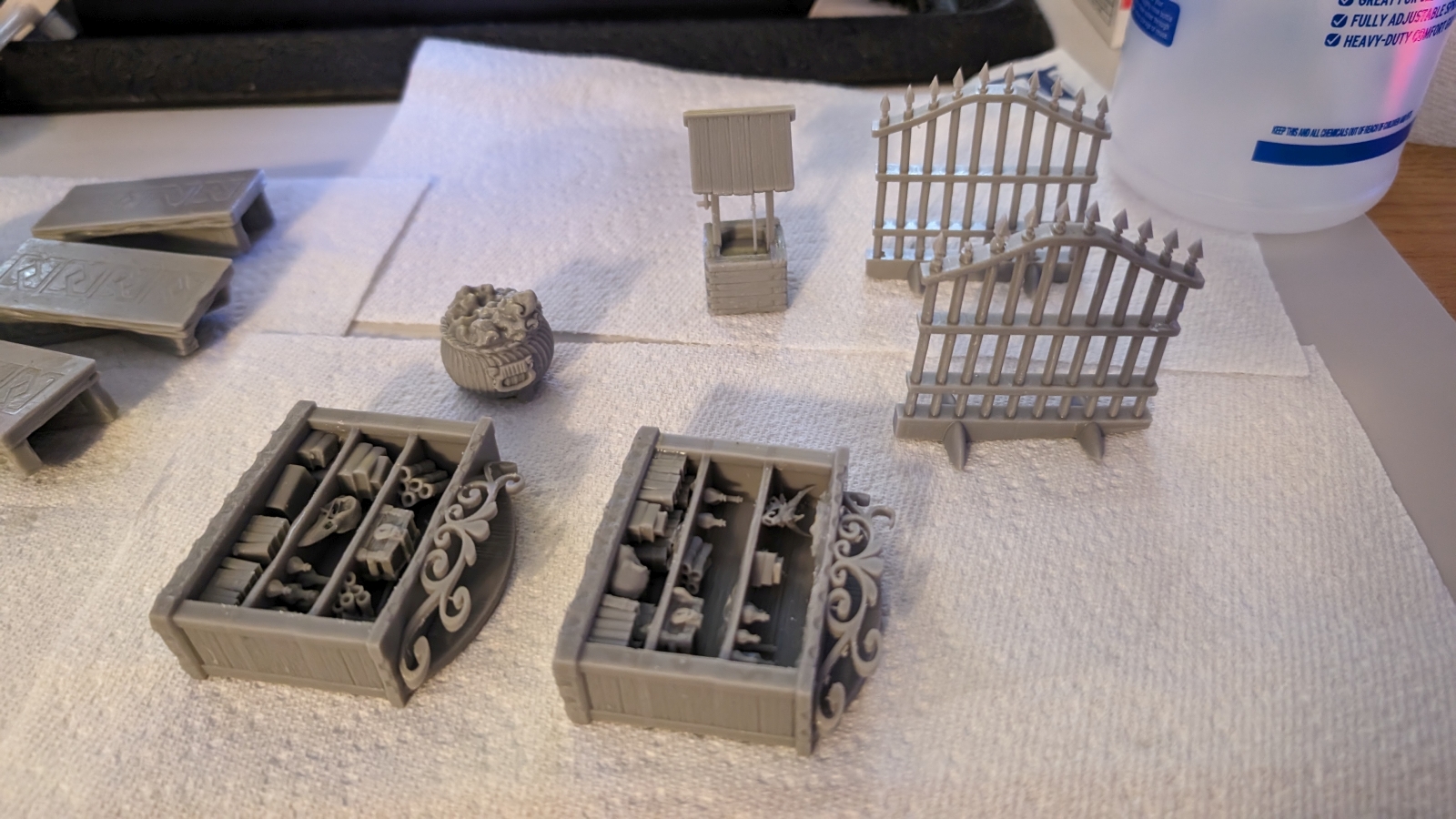

I’ve been 3D printing for a few years at this point. It started with things like chip clips, replacement plastic parts, and fidget toys, and has spun so far out of control that it would probably qualify for a case study of some kind. In Lord of the Rings: Journeys in Middle-earth there are round boulder pogs – those were replaced with well-painted resin rocks. There are cardboard fences as well, now replaced with a variety of similar flavor pieces. Book cases, chests, statues, and more round out that game, which is when I graduated to health counters for Nemesis, flames, caravans, and markers for Return to Dark Tower, and a whole lot of organizers and play boards. Lately I’ve been spending a lot more time printing medium scale high-detail statues and painting them with my wife, Laura. Recently I printed a two foot tall statue of Sylvanas from World of Warcraft for a close friend of mine on my Elegoo Saturn 2 and it taught me a lot about supports, calibrations, and assembly. It also made me want a much larger printer – something that I could make even larger statues, single-piece sculptures, and all without needing to slice it into small parts. Elegoo once again showed me the solution – their new and improved Elegoo Jupiter SE. After nearly two months of calibration and printing, I’m finally ready to talk through the ins and outs of this incredible piece of hardware. Let’s make something amazing.

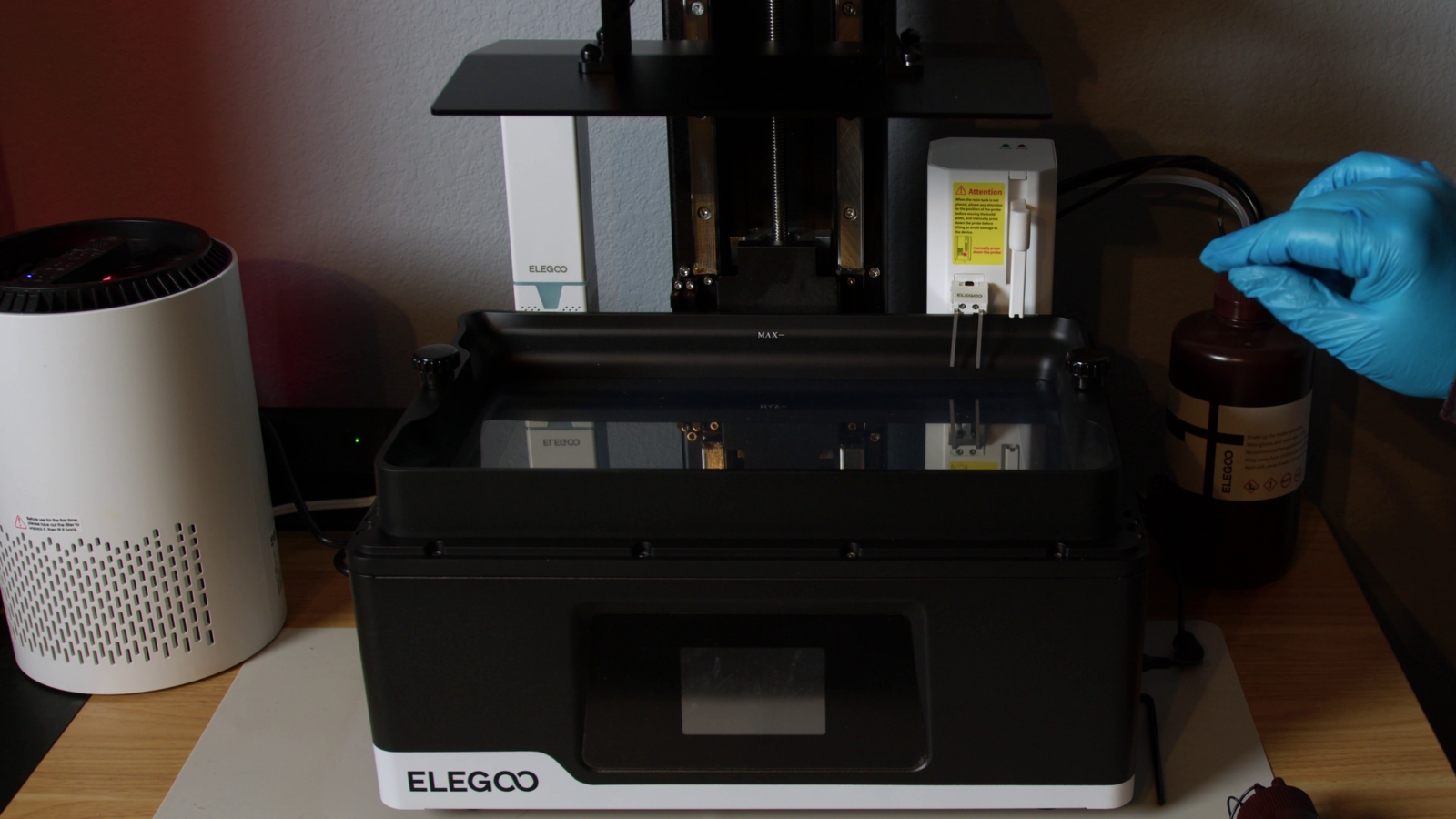

When the box arrived it put a smile as big as the printer itself on my face. Elegoo released the original Jupiter printer on October 10, 2022. A large gray box with a glass door, it came with a number of big improvements over its smaller counterparts, but it was heavy and didn’t really match the aesthetic look and feel of their other printers. Still, it gave a lot of folks their first look at a prosumer level resin printer, with an initial cost of $1300 if you caught it on preorder. That put it in one of the highest price brackets, and there were issues with that gray frosted glass allowing pass-thru curing inside the vat, but overall reviewers found it to be a solid large format printer. Heading into 2024 we see a major refresh of this printer, taking the best parts of its larger brothers and a few from the smaller ones and blending them into something better than the sum of both – the Jupiter SE.

Inside the box is the printer, of course, though the first major change is immediately obvious – it looks like a larger version of the Elegoo Saturn 2 or 3, signature red hood included. Pulling it out of the foam it’s also obvious that it’s far lighter than the previous model, despite having the exact same build volume and resolution, as well as several new or refined features. The usual bag of tools is included (wrenches, some gloves, etc.) as is a USB-powered air purifier and a pair of automatic resin feeding systems. The previous system used a sort of trench-type feeding system with bottles along with an adapter to invert into it. This has been thankfully replaced with an automatic feeding system that we’ll dig into in a minute. To ensure you aren’t having to open a bottle to put more into it mid-print, Elegoo has included two tube systems to ensure you’ve always got a spare ready to go. These connect to the new automatic pump system. Beyond that there’s a USB stick in the box, the resin tray, the build plate, and some thankfully-included handles for the large removable lid.

One of the first new features I noticed is the new pattern on the build plate. Rather than having to take a bit of sandpaper to a smooth surface to scuff it a bit for adhesion, this new build plate attempts to do the same thing with a diamond pattern throughout. After a month of heavy use there were a few scratches throughout the plate, but no damage, so I suppose the hardness hasn’t changed. The nicest accessory you can buy for a printer continues to be a magnetic plate, so I’ll be headed that direction, but once tuned I never had a problem with this improved plate system.

Leveling continues to improve with each printer iteration. While it’s not a perfect system or fully automated by any means, it seems to be more tolerant to being slightly off than previous iterations. As before, the printer comes with a piece of cardstock that’s meant to be left on the screen while you run through the normal leveling process. Four hex head bolts secure the plate, with a large lever on top to lock everything in place. This new mechanism is an improvement over the Saturn 2 and 3’s lock plate, ensuring that it stays in place without the risk of the plate moving to secure it – something I’ve done in the past.

The plate itself is the same size as the older model with a printing size of 277.8 x 156.2 x 300 mm³, or 10.94 x 6.15 x11. This is paired up with a 12.8-inch 6K monochrome 2.0 COB LED LCD. That results in a resolution of 5760 x 3600 px (51 micron XY), with clean and crisp lines, edges, and corners. I’d be comparing it with my 8K Elegoo Saturn 2 which is an 8K printer, albeit with a plate volume roughly a third smaller. In practice, it’s not the height that proves to be a challenge in 3D printing, but the width. It’s rare to print an object with a 300mm height, but it’s not uncommon to need to slice something to fit on the narrower width. For example, all of the items we test printed for this project had base plinths that were able to be printed as a single piece, where they would have been either scaled drastically, sliced in half, or angled severely which risks suction and adhesion problems.

There is a change when you look at the rear of the Jupiter SE. To help prolong the life of the screen, Elegoo has taken a number of steps. The COB LED isn’t directly aimed at the glass, instead using a single point reflection inside the case. This reduces light diffusion, which helps with overall clarity, but also reduces direct heat on your FEP and resin. Additionally, a pair of cooling fans and a heat-conducting copper tube system ensures any heat is pulled away from the resin which ensures a stable temperature. Many people don’t realize that the screen is considered a consumable, but with this new cooling tech it should be a lot longer before that comes to pass.

I mentioned that the original Jupiter had a tinted glass system. While good intentioned, and certainly giving some great aesthetics, it created problems instead of solving them. It added dramatically to the weight of the device, and it made passing final prints more problematic rather than the unobstructed approach offered by the lid. For the Jupiter SE they’ve gone back to this approach, offering the same signature red plastic lid you’ve seen on their other printers, only this time with a set of handles included. In the past I’ve purchased little stick on handles for my other printers, but these are threaded holes to ensure everything stays right and tight. The red color also keeps light ingress to a minimum, though I’d still recommend keeping this or any MSLA printer out of direct sunlight. It’s also much easier to clean, as an added bonus.

Another improvement over the original is the new fill system. Rather than being part of the resin tray, Elegoo has built a pump system for the Jupiter SE. Plugging into the USB port on the right side of the device is a new pump that can both fill and empty the resin vat. Two tubes and a wire come off the pair of included adapters, drawing resin from a 1KG Elegoo resin bottle directly into the vat, which can hold about two liters of resin. It will do so automatically and periodically, doing its level best to ensure you never run out of resin. In practice, I tend to order my resin in far larger quantities than 1KG, so I had to keep a pair of 1KG bottles on hand to refill. Unfortunately every manufacturer uses a different thread type, so none of my other resin bottles fit here either. Yes, it does ensure brand loyalty, but I can’t count this against Elegoo – nobody can agree on a standard.

Draining the vat for a color change, teardown, re-leveling, or cleaning can be a pain. Trying to hold the vat while you pour the contents into a funnel and ultimately the bottle is a recipe for a mess. On the screen is a new button to drain the vat, causing a small tube to descend into the vat and suck the resin back into the bottle. This process takes 2-3 minutes, but will leave a small amount in the bottom. Tilting the vat towards the corner and using a rubber spatula gets the rest out, making cleaning a breeze. The pump uses two metal leads sitting in the vat to detect levels. It’s a remarkably simple system, and frankly one I’d appreciate on all my printers going forward.

Opposite the new pump is an improved USB-powered air purifier. These are the same physical size as the ones for the Saturn 2 and 3, albeit with twice as much activated carbon – an improvement. The new version is meant to last for roughly a year and will run you about $28 bucks for a pair of them. I’m sure somebody with better measuring devices than I have can speak to the efficacy of these filters, but if they aren’t enough there’s also a pre-cut position in the back of the case to attach a full vent system.

Also included in the box is a USB stick. It has a version of Chitubox (Chitubox 1.9.6 Beta01) with a preloaded profile for the Jupiter SE. It also has a trial version of Voxeldance Tango. I personally use Lychee Slicer, but this printer will work with just about any slicer you prefer. Tango is typically used in commercial settings due to its ability to handle larger format printers, but recent updates to both Lychee and Chitubox will handle this printer fine. In a pinch you can use the original Jupiter’s profile since most of your modifications will be made on your resin profile anyway. I was disappointed to find that Voxeldance Tango was a demo version, though, given that it was the full version for the original Jupiter.

With my Z-axis set and my plate leveled I went for broke and printed an unsliced Princess Zelda from Breath of the Wild. Well, “wild” is an appropriate name for what came out of the other end. Layer shifts, splits, and other bizarre failures caused the poor princess to come out looking like a Necromorph from Dead Space. Behold the horror:

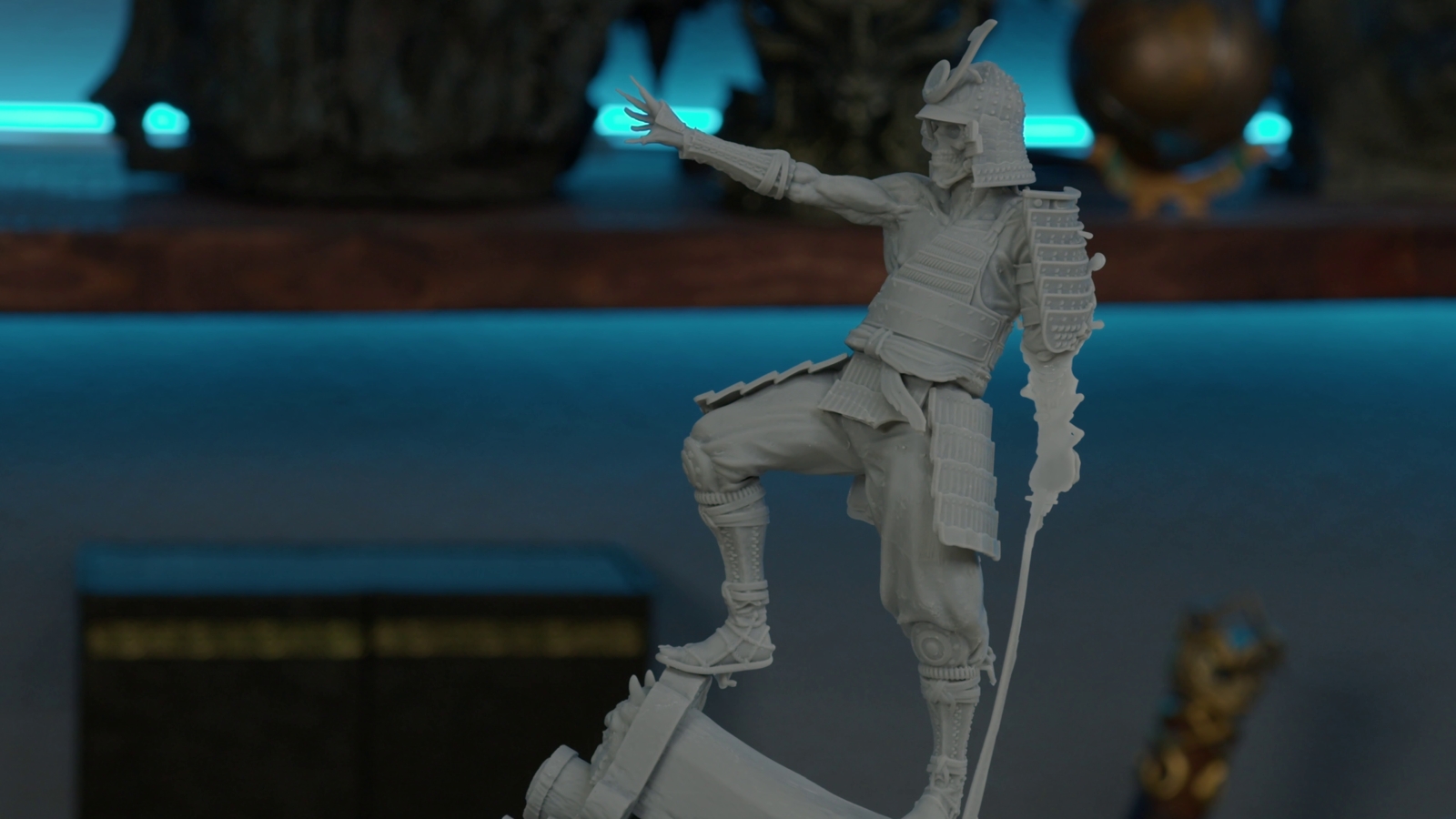

Using the drain function I pulled everything back to the start, re-leveled, and doublechecked my settings with the help of the incredible folks at TableFlip Foundry. Ty, the CEO of TableFlip, is responsible for the frequently-used Cones of Calibration. Using their newest version (which is practically an adventure game, with a skull, sword, and cones!) I dialed in my resin, layers, speeds, and printer functions. I also switched up to an undead samurai because I have the attention span of a toddler. This second attempt went far better, but still had a few problems. You can see some incredible sections on the warrior, but you can also see where an error caused it to stretch his sword out flat, melted some supports flat, and ruined the rear of the body. Slightly less horror…

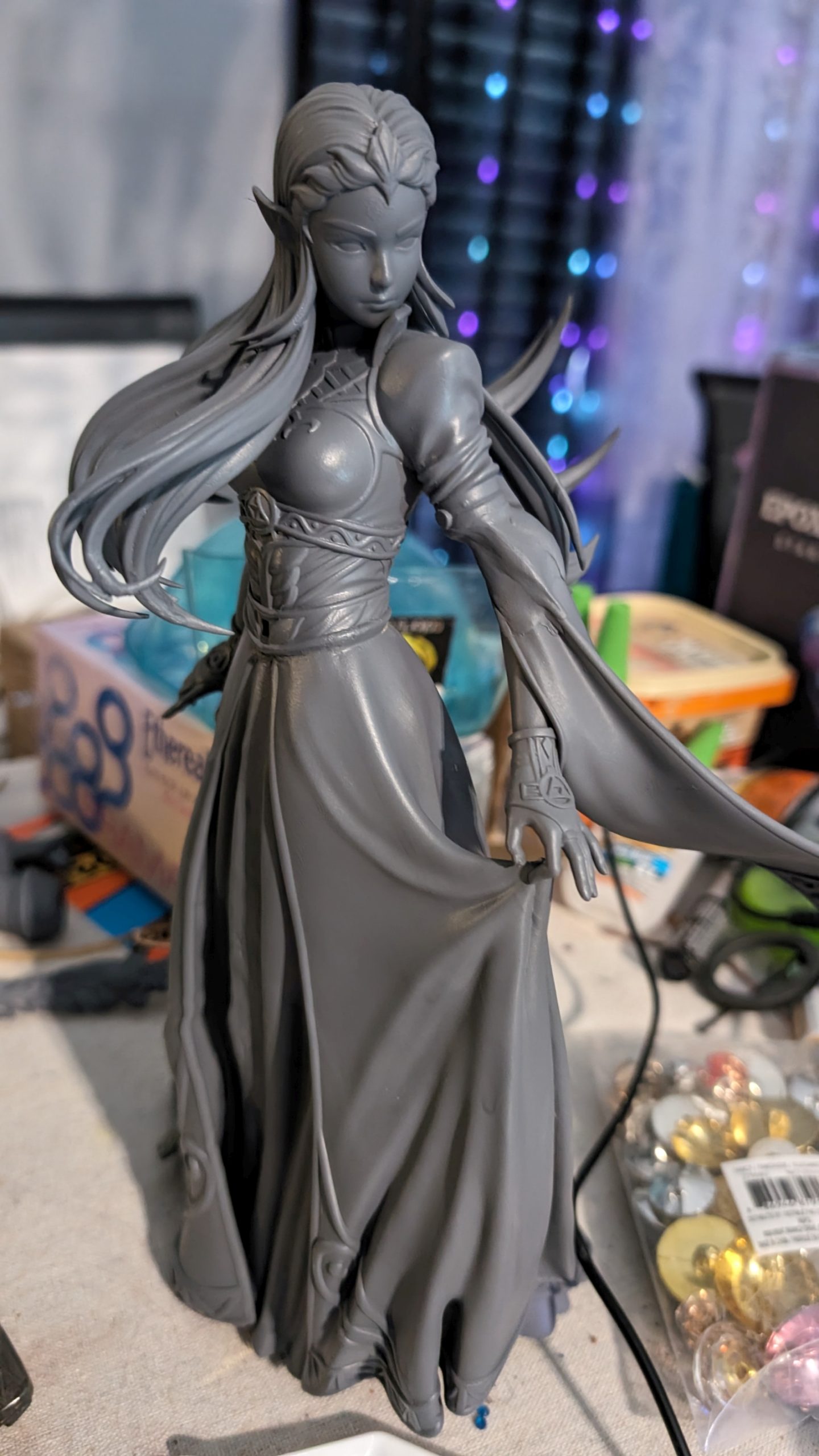

Eager for a win, I tackled the Princess Zelda print, but sliced up. Unwilling to compromise, I also scaled it up to 170%. I could describe how that went, but a picture is worth a thousand words, so they say. Let’s see it.

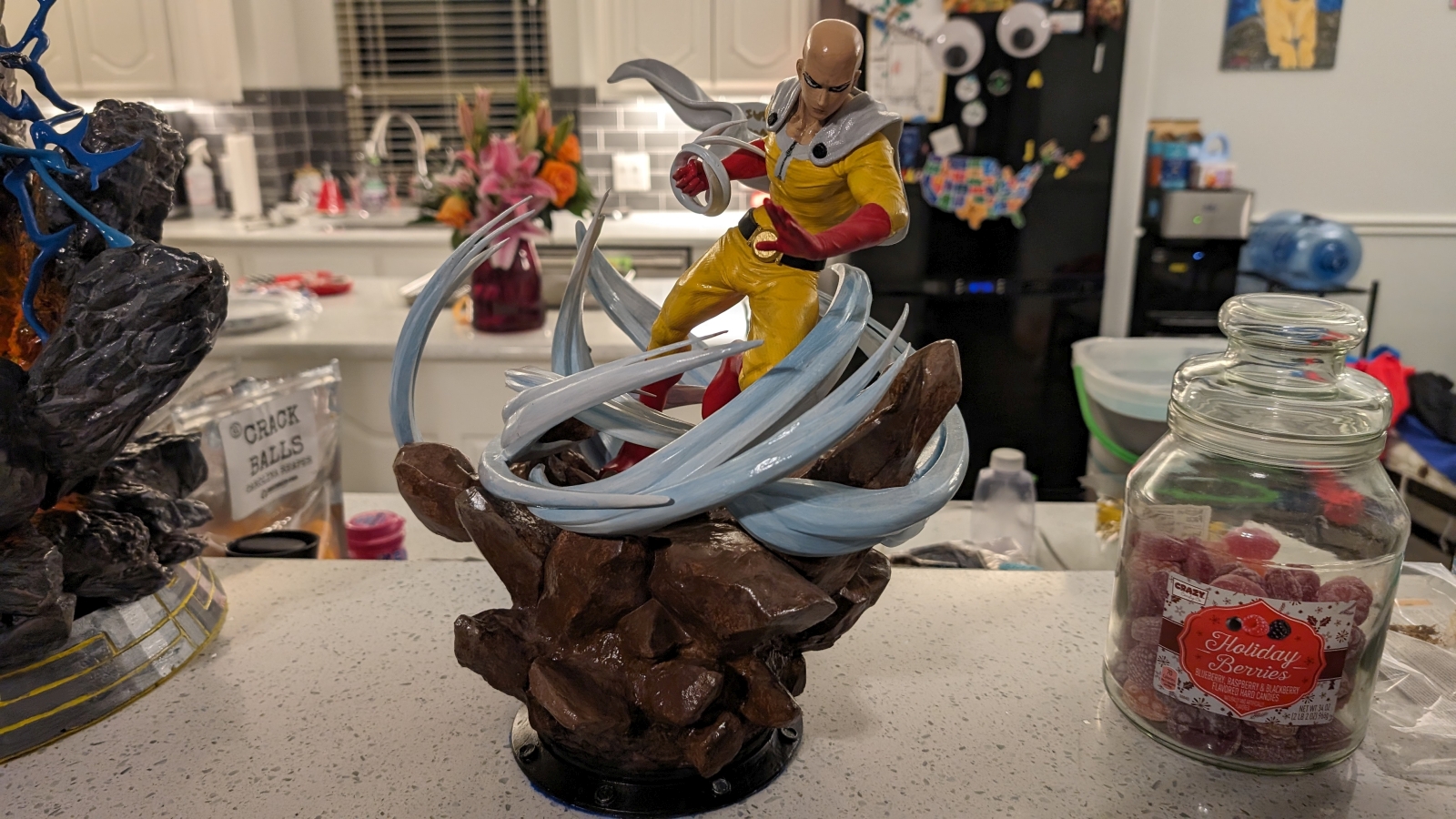

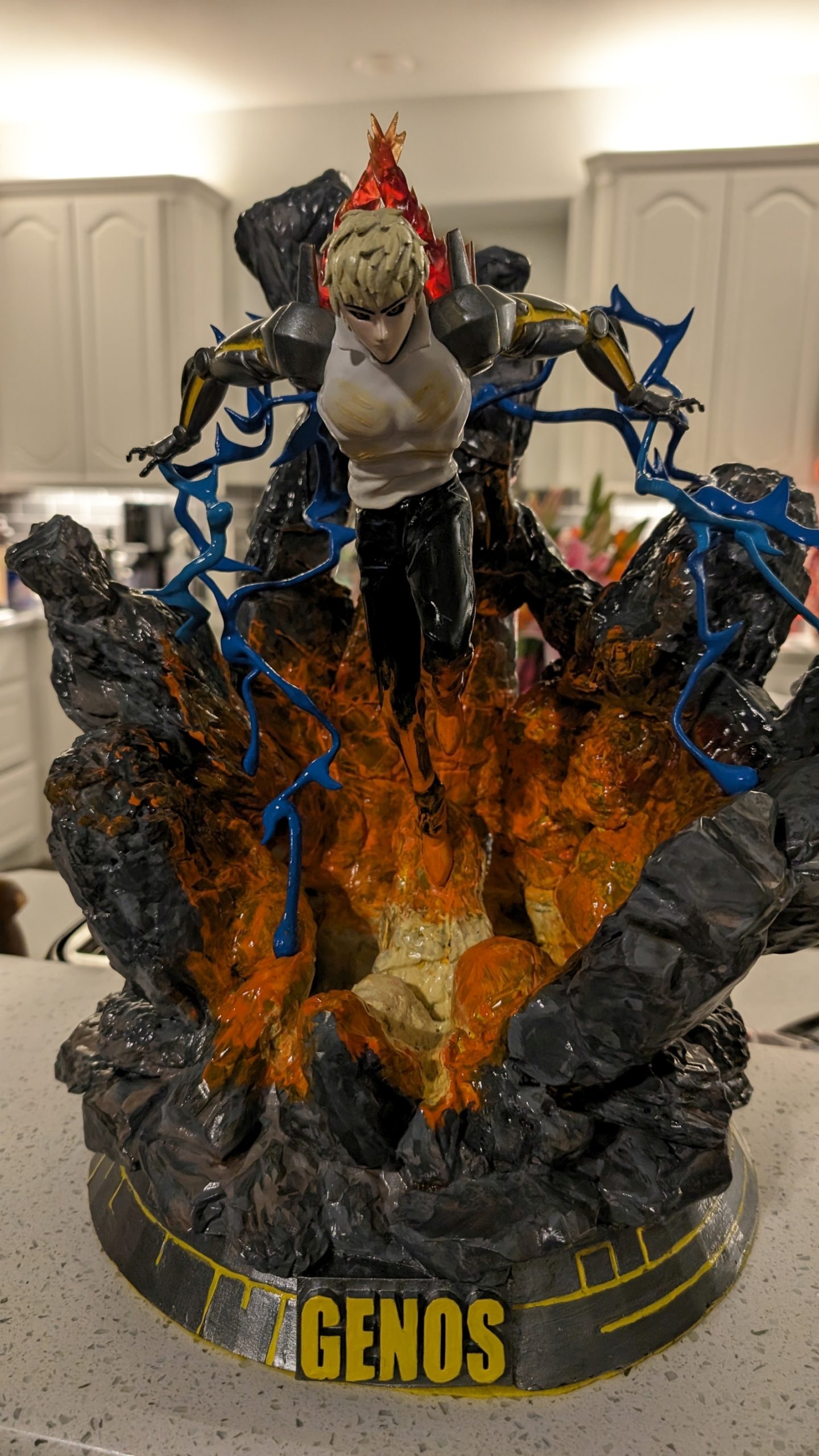

There we go! I was able to get a beautiful print out of the Jupiter SE, which gave me some basis for comparison to the higher resolution 8K Saturn 2. I was surprised to see just how little difference there is between those two devices. Yes, if you inspect very, very closely you can spot the occasional layer line. A bit of sanding and fill work by Laura cleaned up any of that, and once primered it was almost impossible to tell the difference. Eventual paint work will solve the rest.

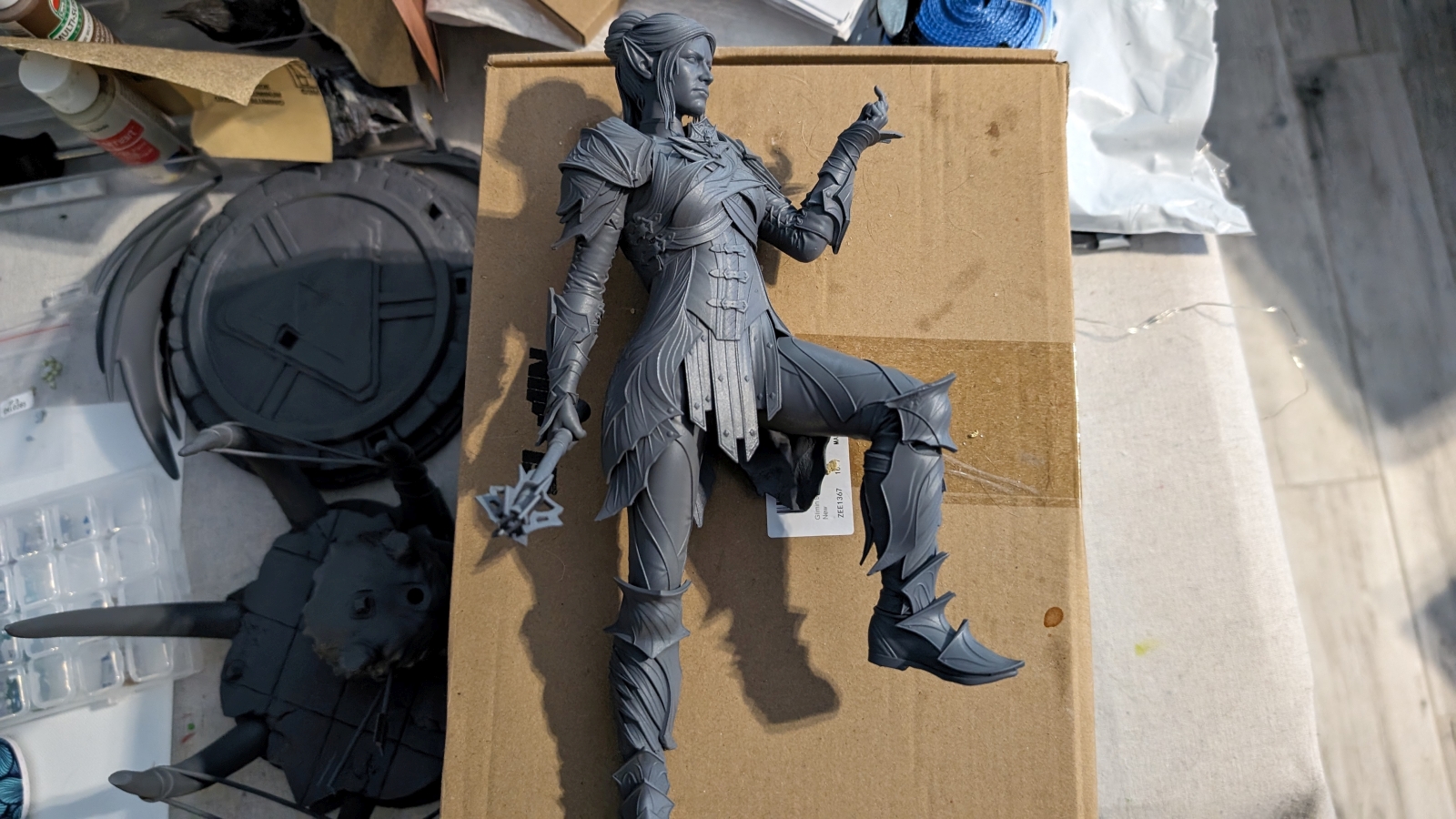

Undeterred, and emboldened by my Zelda success, I wanted to print something to maximize the build height of the system in a single build. Not only to showcase the capabilities of the printer, but to see how the Jupiter SE would handle a whopping 31 hour print. I couldn’t think of a better choice than H3ll Creator’s Minthara from Baldur’s Gate 3. Scaled up to 205 percent, and by printing the base and bear head separately, I was able to maximize the full 300mm of build height for the printer. I’m very happy to report that, after a few bumpy starts, it did exactly that.

As you can see, the results are absolutely flawless. Zero layer lines, shifts, or defects. It took a bit of calibration and small tweaks and adjustments, but there’s no denying the results.

Looking at this print, it’s certainly large, but it could be larger. The challenge of a single object print is that you are courting disaster. If all goes well, there’s no additional assembly, seam repair, or other challenges. If it doesn’t, you are looking at another very long print, and a lot of wasted resin in the process. By printing in pieces, you can scale up even further. I’ve personally printed states double the size of Minthara, but in much smaller chunks. It allowed me to scale to the precise size I wanted, re-print anything that needed to be adjusted (e.g. I hollowed the arm, hand, and light saber for an upcoming LED-powered assembly of Darth Talon), and with minimal waste.

There was one thing that the Elegoo Jupiter SE exposed about my printing station – it’s just not big enough. More specifically, my wash and cure station was struggling to accommodate some of these larger prints – I’ll need to invest in something larger like the Elegoo Mercury XS to be able to wash and cure models of this size.

I ran into one persistent issue with the resin fill system. The cutout for the tubes in the rear is small to minimize any smells escaping, but it does mean you’ll end up hitting the tubes with the hood almost every time. As such, it knocks the fill system askew slightly, resulting in an error frequently. Some sort of locking mechanism to hold it from moving would be nice as having to pull the hood over and over and carefully place it like some sort of resin printer Jenga is irritating. It’s a minor nitpick, but one you’ll absolutely encounter if you use the automatic fill system, which I do recommend – it’s very useful.

As with all of our hardware reviews, the last stop on the trip is warranty and price. The launch price for the original Jupiter was $1300 if you caught it at pre-order, or $1500 if you missed the Kickstarter. The Jupiter SE is currently selling for $700, down from the full MSRP of $1000. That’s a pretty significant savings over the previous model, despite all of the improvements. The warranty for the device is 6 months for the screen (up from 3 months for the previous model) and 12 months for everything else. Sure, it’d be nice to see a longer warranty, but that’s fairly standard for this industry.

The thing I appreciate most about the Jupiter SE is that it very clearly demonstrates Elegoo’s commitment to listen to their customers. Every improvement to the Jupiter SE came directly from customer feedback, and all to the better. The revamped ventilation system, the return to form on the hood, the redesigned resin feed system all makes for a better experience for even a novice user. The vastly improved price is icing on the cake, and when your prints come out this big and looking this good, what a delicious cake it is.