3D tech gurus SUNLU have a new goodie to share for filament printing solutions. Today they launched the FilaDryer E2, a new product capable of drying advanced filaments including more complex materials like Nylon and PC, pushing drying temperatures up to 110°C (that's 230 °F for those of us in North America) – a staggeringly powerful dryer sure to drive all of the excess moisture from the material. Why does this matter? Well, if you've ever had multiple filaments breaking, clogging, or otherwise producing less-than-awesome end results, you understand the need. Let's hear from SUNLU about the device and the tech behind the scenes. I'll see if I can drop in a few pics to bring this announcement to life:

Filament drying is the process of removing excess moisture from 3D printing materials before use. Many filaments, especially engineering-grade ones like Nylon and PC, are hygroscopic - meaning they absorb water from the air. If these filaments aren’t dried, the trapped moisture can vaporize during printing and cause issues like weakened part strength, surface imperfections, and inconsistent extrusion.

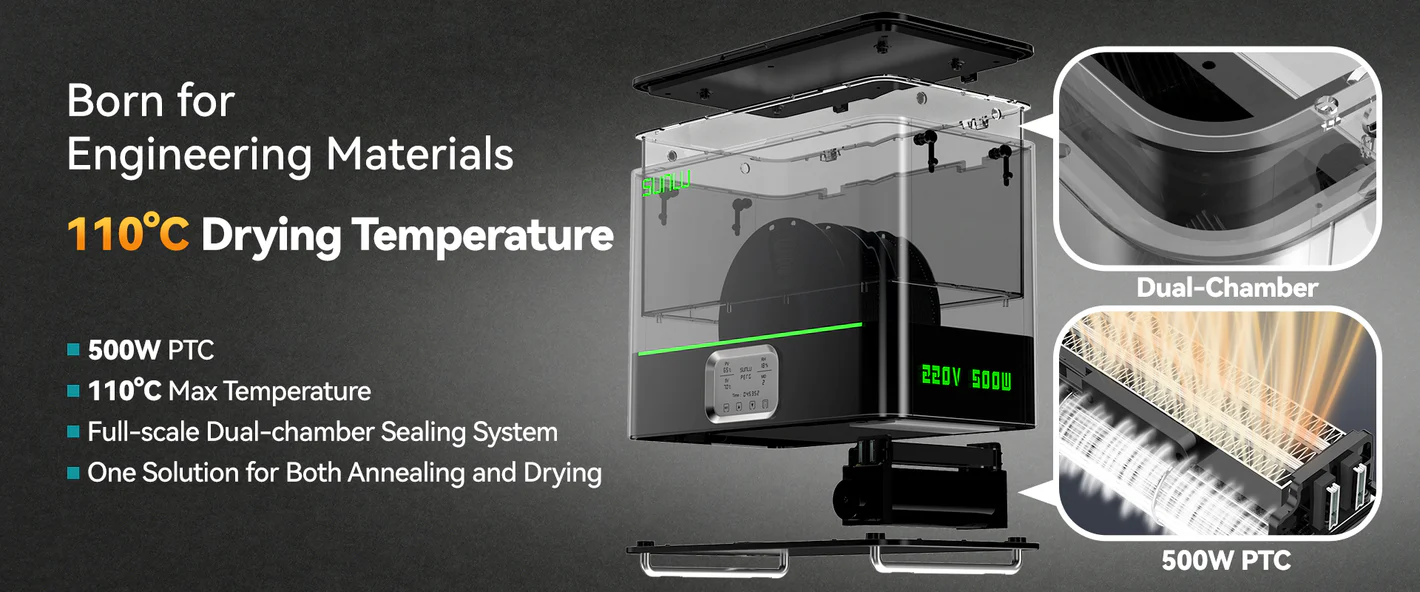

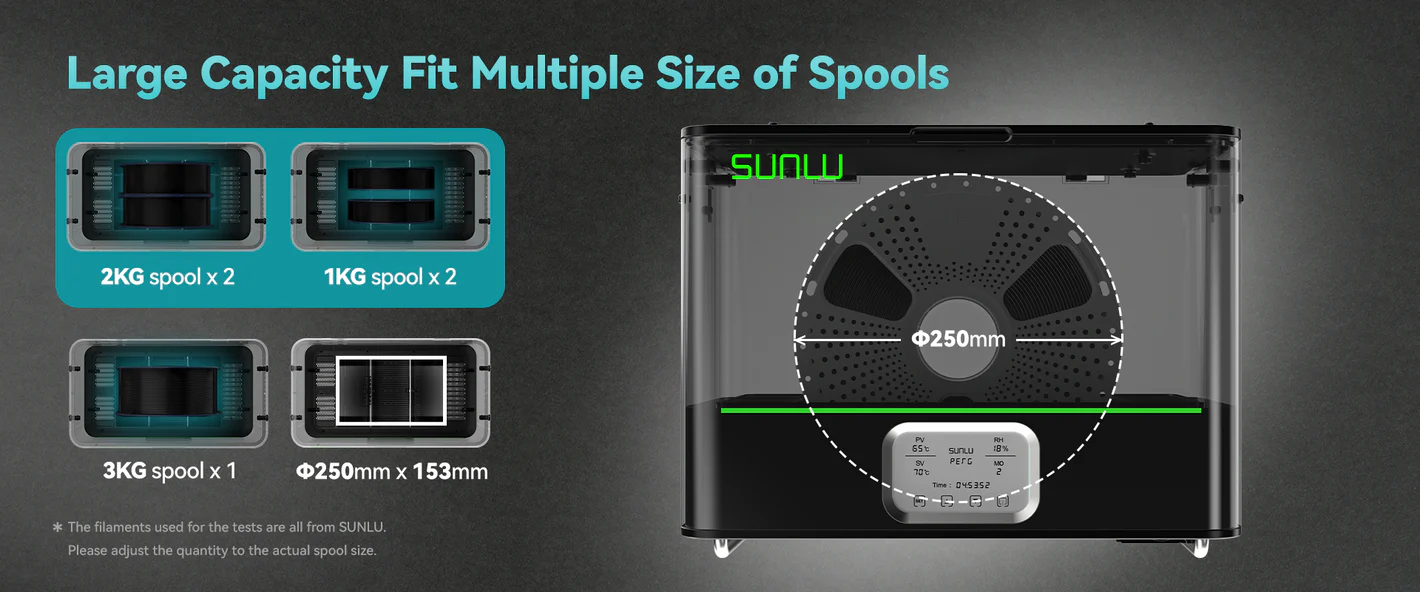

The FilaDryer E2 incorporates precise temperature control to maintain stable and uniform heat levels. In an environment of 25°C (±5°C), the system can sustain up to 70°C with ±3°C accuracy. Between 70°C and 110°C, it offers ±5°C accuracy based on measurements taken at four different points - enabling consistent drying for professional-grade results. With internal dimensions of 372mm × 192mm × 186mm, the FilaDryer E2 can accommodate two 1kg spools, one 2kg spool, or even one 3kg spool - giving users the flexibility to dry various spool sizes in one device. A spacious chamber, paired with eight outlet holes and quick connectors, allows multiple filaments to feed out simultaneously while silicone plugs help retain a sealed environment when not in use.

The user-friendly touchscreen, adapted from SUNLU’s S4 series, enables simple operation for tasks such as adjusting temperature and customizing drying or annealing cycles. Even near the upper limit of 110°C, the product’s surface temperature remains below 55°C, which helps ensure safe handling. The FilaDryer E2 supports filament diameters of 1.75mm, 2.85mm, and 3.0mm - accommodating a wide range of consumables, including popular engineering filaments that often demand strict drying and heat-treatment conditions. By integrating UL, CE, FCC, UKCA, and ROHS certifications, SUNLU upholds stringent global safety standards.

In addition to its drying capabilities, the FilaDryer E2 introduces an annealing mode for users seeking to strengthen or stabilize their prints post-processing. This feature presents a valuable tool for professionals who work with filaments that perform best under controlled heat treatment.

If you are unfamiliar with the annealing process, it's the same method that companies like Lockheed Martin use to bake in the various stealth technologies and radar-repelling skin onto their planes. It's also used to remove any additional impurities and materials that might otherwise cause imperfections in the end result. It's an amazing process to see in person, requiring incredible heat and control of the environment. To see that same process brought to 3D printing really underscores just how seriously SUNLU is taking this upgrade.

By carefully heating the finished print to a specific temperature, annealing helps relieve internal stresses, improve dimensional accuracy, and enhance mechanical properties - making components more durable and reliable in demanding applications.

The new device also integrates more subtle details, such as ensuring minimal moisture reabsorption and offering quick connections for Teflon tubes, which streamline workflows in multi-printer setups.

With the launch of the FilaDryer E2, SUNLU further reinforces its position in the industry - anticipating and meeting the evolving demands. As the company expands its engineering materials portfolio and refines its products through regular updates, users can expect an ever-improving suite of features.

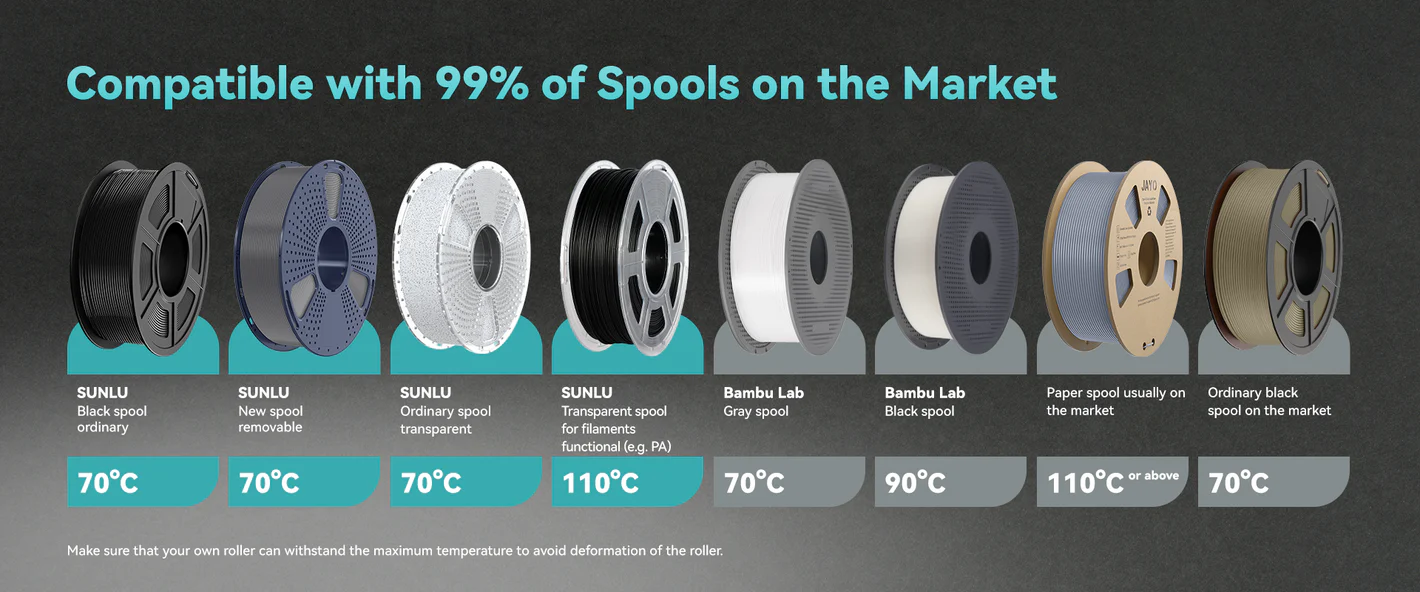

Digging into the specs, we see some great features that look like it'll work for just about ANY filament you could possibly use.

[Superior and Efficient Annealing] Up to 110°C, it can anneal 99.99% of engineering materials on the market, allowing the materials to fulfill their potential and giving your model excellent properties such as extraordinary impact resistance and toughness. Suitable for such as ABS, ABS-CF, ASA, PC, flame retardant PC, PC-ABS, PC-PBT, CoPA, PA6-GF, PA6-CF, PA12-CF, PA612-CF, PA12 etc...

[Fast and Efficient Drying] 500W PTC ultra-high heating power makes your creation a step faster. It takes only 20 minutes to heat up to 50℃ at room temperature and 30 minutes to heat up to 70℃! Temperature can reach up to 110℃ (high temperature drying needs to take into account the temperature resistance of the filament spool)

[Excellent Airtightness, Super Insulation Effect] One-piece silicone plug over the line hole, the cover plate is equipped with sealing silicone strips and magnetic suction block, to isolate the outside water vapor into the chamber. The all-round dual-chamber design at the top, middle and bottom realizes the heating temperature exceeding 100°C. Combined with the innovative closure system, the annealing process is more perfect, solving the two needs of annealing and drying in one machine.

[Extra Large Interior Space, Super Adaptability] The maximum compatible spool size is Φ250mm*153mm, which is suitable for most of the regular spools on the market. Tested, it can hold 2 reels of regular 1KG spools, 2 reel of regular 2KG spools or 1 reel of regular 3KG spools. (Note that the test spools are SUNLU spools, other brands of spools will have slight differences, but basically compatible, when using the need to pay attention to the size of the spool.)

[Strong Compatibility, Adapts to 99% of the use scenarios] Can be applied to both engineering materials and conventional materials. Built-in preset filament settings, one click to apply the preset. The wire diameter is compatible with most of the materials on the market (Φ1.75mm, Φ2.85mm), and the Teflon tubing included with the product is Φ4*Φ3mm in size and 8cm*2 and 1m*2 in length.

[Strong Safety, No More Worries] Intelligent protection system, two-level temperature control switch, over-temperature will be disconnected, cooling will be restored. Double-layer heat insulation, when the internal temperature is >100℃, the external touch temperature is only <60℃. Fireproof material grade

[Inspire Engineering Material Potential] Annealing significantly enhances the impact resistance and durability of engineering materials, allowing you to unlock engineering-grade performance in every creation, which can be applied to: drone accessories, helmets, screws and nuts, blower pipes, etc. Models that need to withstand high-intensity impact and durability.

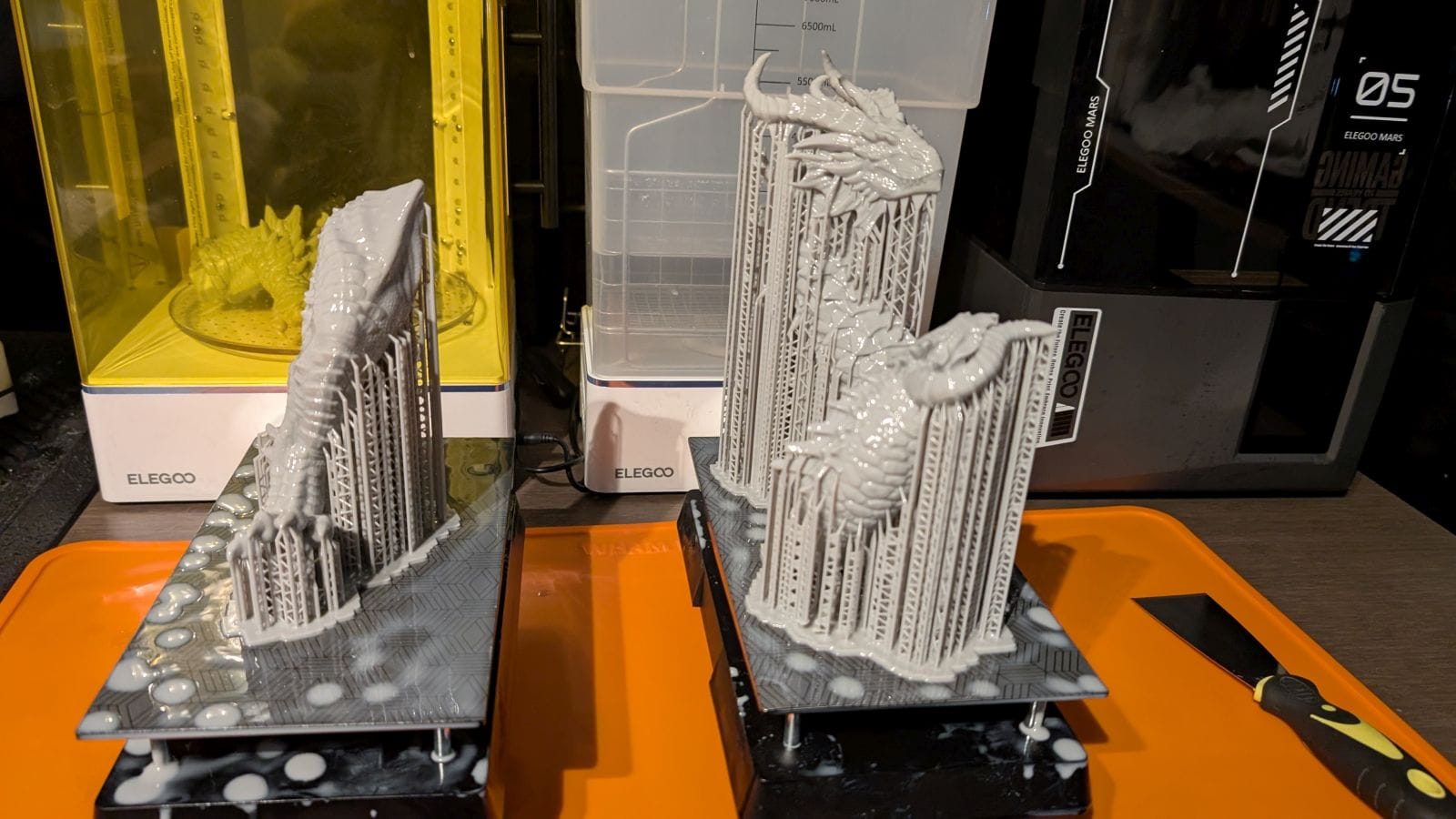

We've got a cool partnership with SUNLU ahead of the upcoming TFT Expo – a massive build of a castle in filament, a HUGE dragon in resin, and maybe even a surprise dice tower to cap it all off. We'll have more to share on that soon, but here's a quick preview...

Stay tuned as we wait for additional information on pricing and availability, but it's looking like May 2025 to get these in your hot little hands.